What safety shoes are the best to wear on construction sites?

Construction sites are dangerous places. You need shoes that protect your feet from falling objects, sharp materials, and slippery surfaces. Without proper footwear, you risk serious injury.

The best safety shoes for construction sites have steel toes, slip-resistant soles, and puncture-proof midsoles. They should meet EN ISO 20345 standards (S1-S3 ratings) for workplace safety. These features prevent common hazards like crushing injuries or chemical spills.

Construction workers face different risks every day. Their shoes must handle heavy loads, wet conditions, and long work hours. Let’s examine what makes safety footwear suitable for tough job sites.

What is the best footwear to use on a construction site?

Construction sites demand rugged protection. Ordinary shoes won’t shield you from nails, concrete spills, or heavy equipment hazards.

The best construction site footwear combines steel toe caps, oil-resistant soles, and waterproof materials (S3-rated). Look for shoes with ankle support and shock absorption for full-day comfort. These features reduce workplace accidents while preventing fatigue.

!

Three key factors determine ideal construction footwear:

-

Hazard Protection Level

- Steel toes: Protects against 200J impacts (20kg object falling from 1m)

- Midsole puncture resistance: Stops nails up to 1.1kN

- Slip ratings: SRB (oil-resistant) or SRC (oil+acid resistant)

-

Comfort Features

Feature Benefit Cushioned insoles Reduces foot fatigue Breathable lining Prevents sweat buildup Lightweight design Eases all-day movement -

Environmental Adaptability

Wet sites need waterproof membranes (S2/S3). Hot climates require ventilated designs. Always match shoes to your specific work conditions.

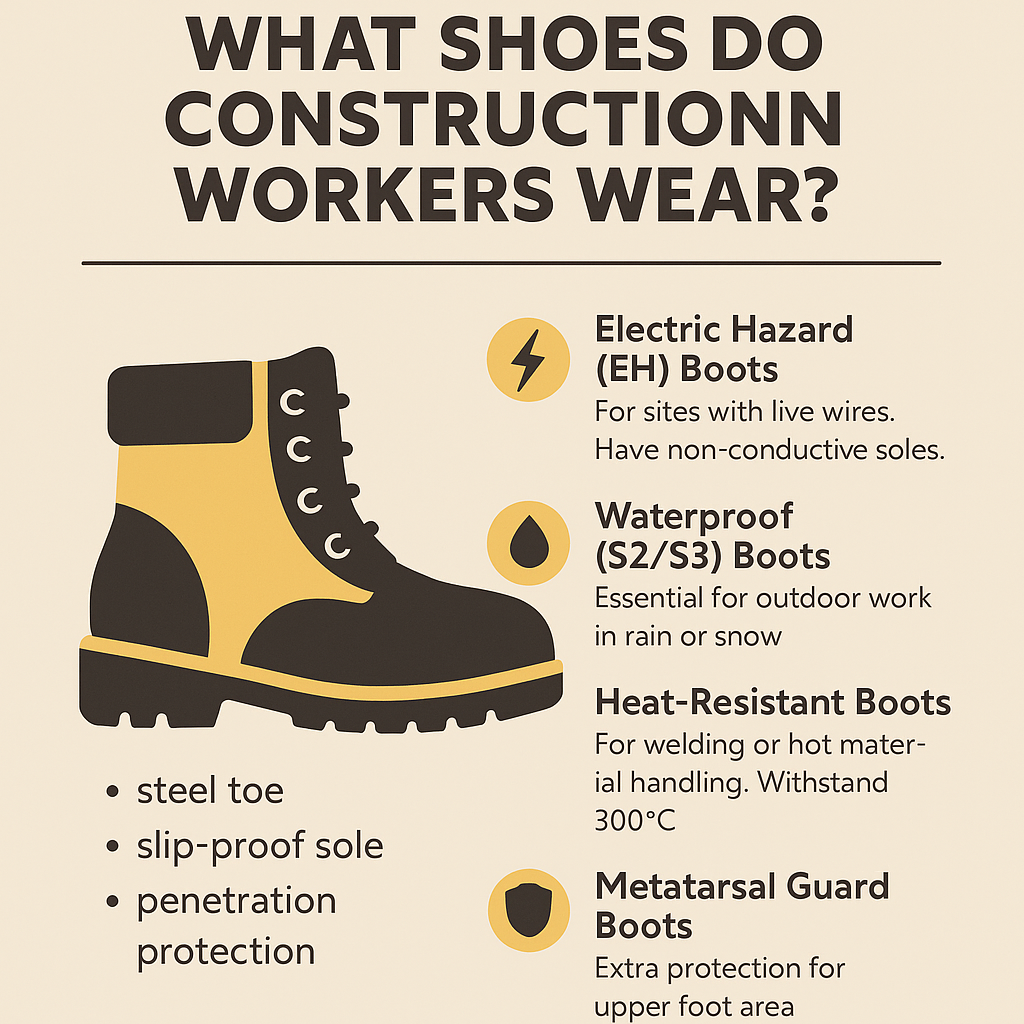

What shoes do construction workers wear?

Most construction crews wear lace-up boots or sneaker-style safety shoes. The choice depends on mobility needs and workplace hazards.

Construction workers typically wear S1P or S3 safety shoes—steel toe boots with slip-proof soles and penetration protection. Many prefer 6-inch ankle boots for extra stability on uneven ground. These offer the best balance of safety and comfort.

![construction crew footwear]

Here’s a breakdown of common options:

Electric Hazard (EH) Boots: For sites with live wires. Have non-conductive soles.

Waterproof (S2/S3) Boots: Essential for outdoor work in rain or snow.

Heat-Resistant Boots: For welding or hot material handling. Withstand 300°C.

Metatarsal Guard Boots: Extra protection for the upper foot area.

Workers doing heavy lifting often choose boots with:

Thick rubber outsoles

Reinforced toe guards

Shock-absorbing heels

Can you wear safety shoes on a construction site?

Yes, but they must meet specific safety grades. Not all “safety shoes” qualify for construction work.

Only EN ISO 20345 certified shoes (S1-S3) should be worn on construction sites. Basic steel toes aren’t enough—they need anti-slip soles, energy absorption, and often waterproofing. Cheaper industrial shoes may lack these critical features.

![safety certification labels]

Construction-grade shoes must pass 5 key tests:

- Toe Impact Test: Steel cap withstands 200 joule impact

- Compression Test: Toe area resists 15kN pressure

- Slip Resistance: Sole passes wet/dry surface tests

- Penetration Resistance: Midsole stops sharp objects

- Electrical Hazard: Some models block 18kV current

Compare shoe types:

| Type | Best For | Not Suitable For |

|---|---|---|

| S1 | Dry indoor sites | Wet conditions |

| S2 | Damp areas | Chemical exposure |

| S3 | Outdoor construction | Electrical work |

What are S1, S2, and S3 safety shoes?

These European safety ratings define protection levels. Each grade adds more defensive features.

S1 safety shoes have basic toe protection and anti-static soles. S2 adds waterproofing. S3 includes all S2 features plus puncture-proof midsoles—making them ideal for construction work. The higher the number, the greater the protection.

![safety shoe ratings chart]

Here’s a detailed comparison:

S1 Characteristics:

- Closed heel

- Antistatic sole

- Energy-absorbing heel

- Basic toe protection

- Common in factories, warehouses

S2 Upgrades: - Water-resistant upper (2cm water for 1 hour)

- Better sole grip

- Used in food processing, light construction

S3 Advantages: - 1.1kN puncture-resistant midsole

- Deep tread patterns

- Reinforced toe bumper

- Essential for construction, mining, logging

For most construction sites, S3 provides the complete package: - Crush protection

- Slip resistance

- Waterproofing

- Puncture defense

- All-day comfort

Conclusion

Choose S3-rated safety shoes with steel toes, slip-proof soles, and waterproofing for construction sites. They offer complete protection against common workplace hazards.